Date: 2025

Architects: Frank Barkow, Regine Leibinger

Team: Frederick Horton, Federico Lepre, Adin Rimland, Andreas Moling, Stefan Sauter

Student Build Team: Evan Altenburg, Sebastien Bartlett, Aaron Beebe, Paula Cano, Yashna Gondal, Madelaine Hamilton, Grant Mootz, Rohaan Saripella

Exhibition: Pavilion - University of Texas

Photography: Peiying Yang

Role: Adin Rimland was a Project Architect for this project while working at Barkow Leibinger. His role included design development, material research, and coordination with collaborators and fabricators. The project is hosted on Barkow Leibinger’s website — please visit the official page for full documentation: https://barkowleibinger.com/en/projects/2x4-texas-a-frame

Image Courtesy of Barkow Leibinger

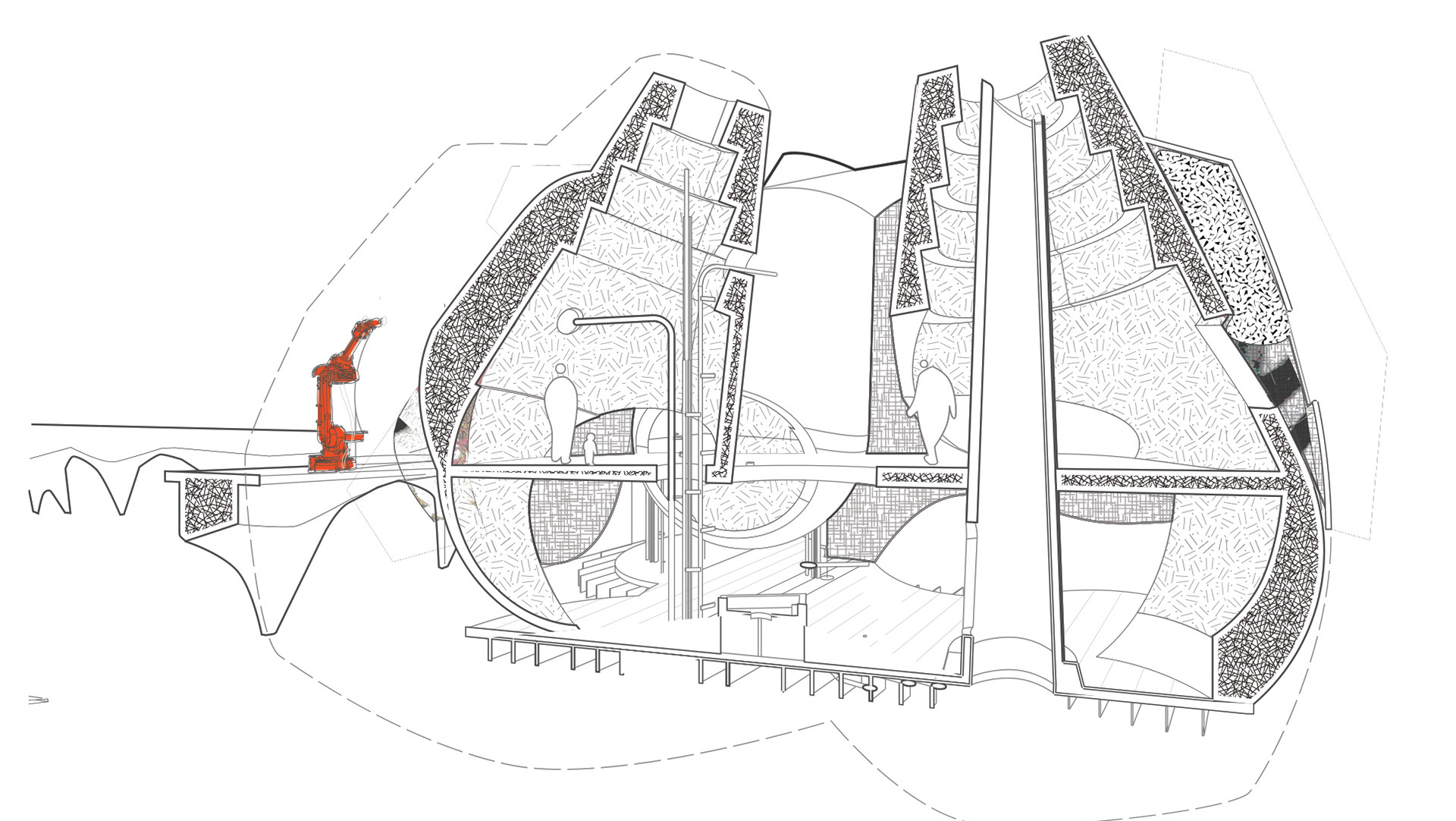

The A-Frame acts as “structure as space” that is, the triangulated trusses are both structurally rigid and spatially accommodating interior programming.

The American A-Frame became a ubiquitous structural solution for low-cost housing usually in the form of a holiday house, ski cabin, or weekend get-away in post-war USA. Formally simple but ingenious this typology was constructed throughout the USA as a small shelter with limited programmatic uses: a bedroom, living room, kitchen, and perhaps a loft. Despite its structural clarity and simplicity, it was rarely expanded beyond its limited project scope. Its distinct sloping walls were strange and challenging. How did you fit the dishwasher in? You had to hang the chimney from the roof and etc.

Like the geodesic domes of Buckminster Fuller, the A-Frame was never developed beyond its demonstrative, do-it-yourself, out of the catalog reality. In a word these ideas never really become architectural with all the complexities, nuances and aspirations that architecture embodies. The A-Frame never really makes it out of the DIY pages of “Popular Mechanics” or on the other side of the coin “The Whole Earth Catalog”. With the advent and promise of digital production capabilities for prefabricated truss construction coupled with a new urgency for sustainable timber construction we feel this is a ripe time to reconsider both the A-Frame and stud frame wall building as an architectural problem offering an economical/sustainable solution.

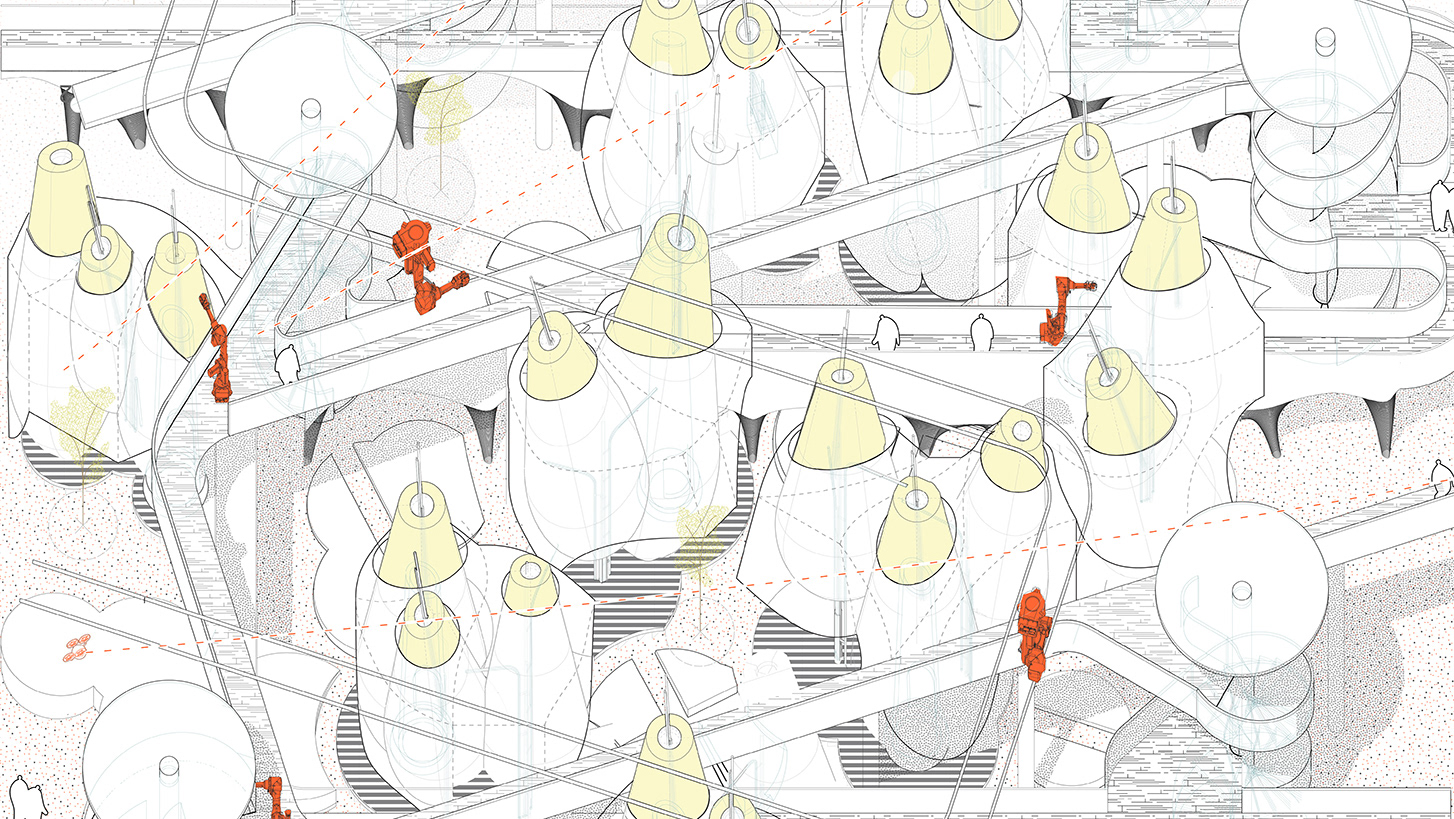

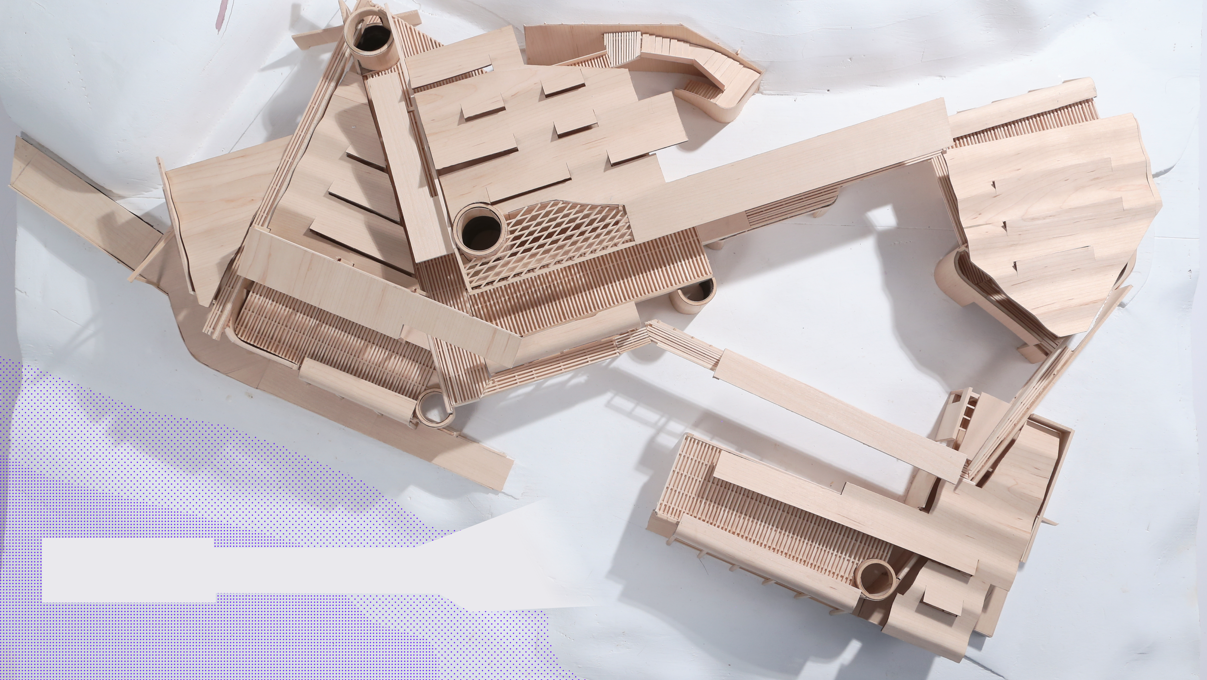

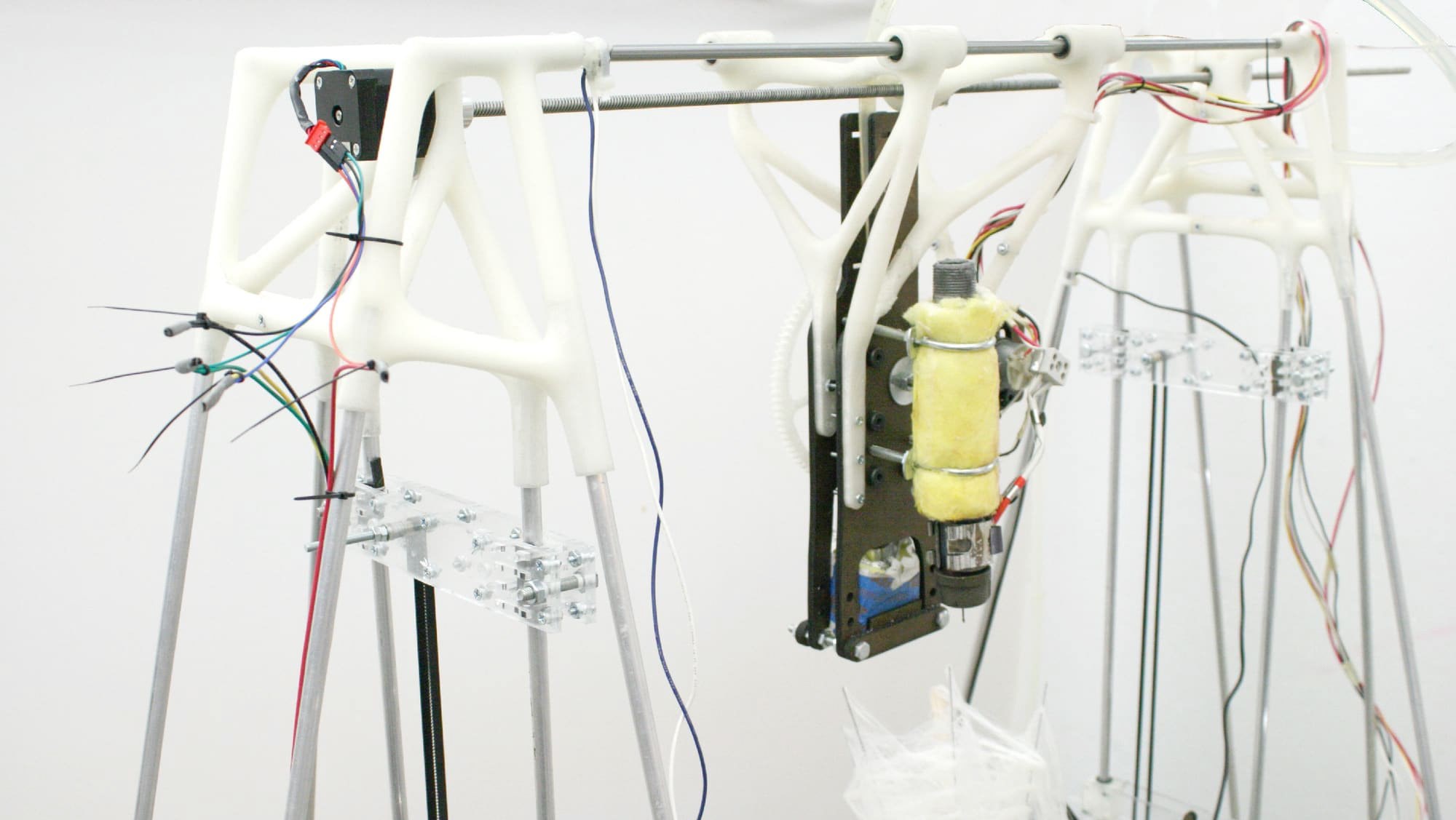

The 2x4 wood stud, typically milled from Douglas fir, finishes at 1-1/2” x 3-3/4” and remains one of the most economical and versatile elements in American construction. Soft enough to fasten easily yet structurally sound, it’s ideal for house framing. With growing interest in lightweight, prefabricated, and sustainable timber design, we re-examine the A-Frame as a contemporary typology—modular, adaptable, and more spatially complex.

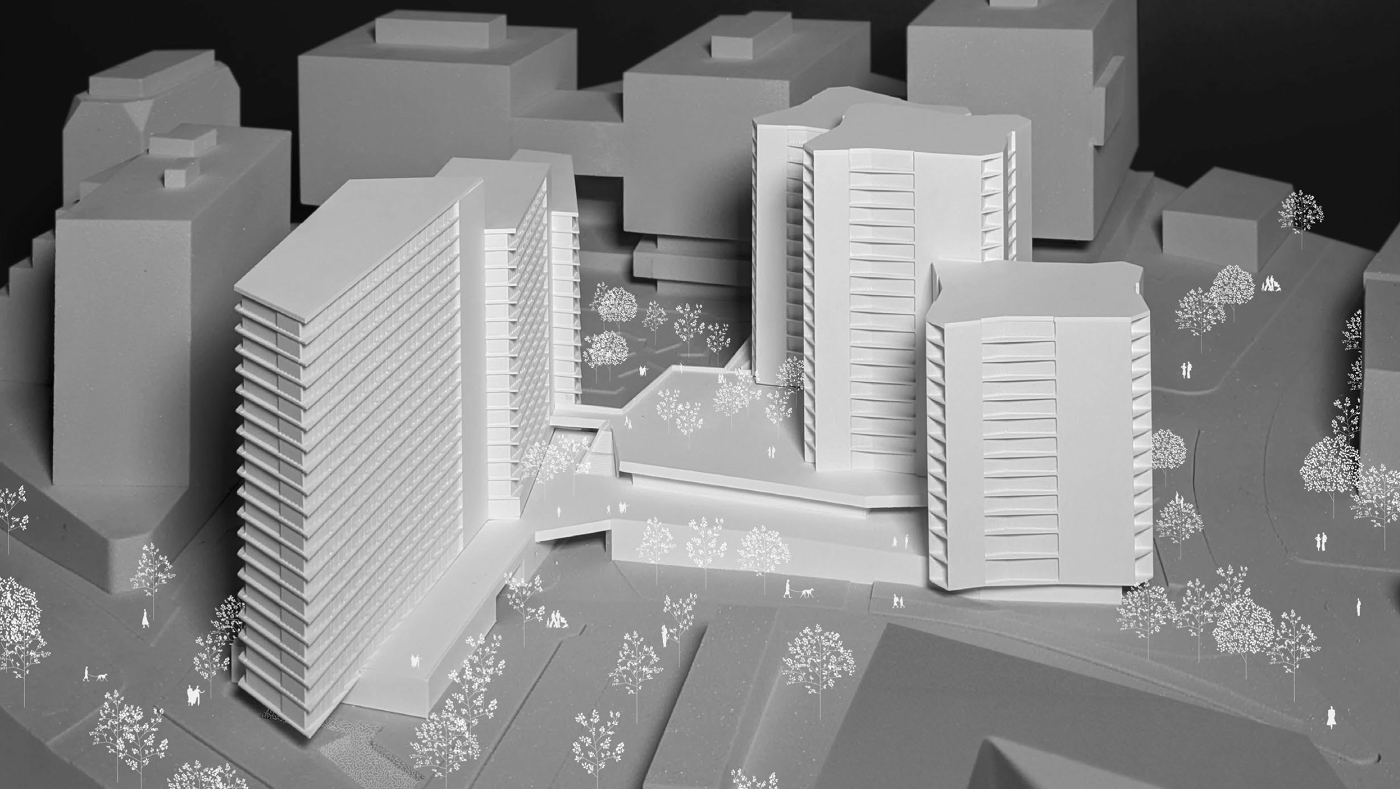

Our prototype for the Mebane Gallery explores this potential. The A-Frame acts as both structure and space: triangulated trusses provide rigidity while enclosing functional zones—kitchen, workspace, sleeping, storage, bathrooms. The units (four in this case) butt together to create continuous yet varied sections, and can step with a site’s topography. Threaded bolts join the 2x4s, forming stiff truss frames. Secondary framing supports furniture and built-ins, with a freestanding Enzo Mari-style table echoing the DIY ethos.

Placed on a site-specific slab-on-grade foundation that also serves for heating and cooling, the structure can be clad with triple glazing, translucent polycarbonate, and photovoltaic panels to achieve Net-Zero performance. It can collect gray water and support rooftop planting. For under $100,000, this prototype offers a customizable, sustainable living model—both familiar and newly relevant.